Rock Instrumentation

Closure Poles

RESPEC’s closure poles are used in underground mining operations to typically measure roof-to-floor convergence but can be retrofitted to measure potentially unstable ground. RESPEC’s closure poles are easily installed and can be retrieved and redeployed as needed. Closure poles are offered in long-travel “Thinpot™” and short-travel “Springpot” displacement sensor options.

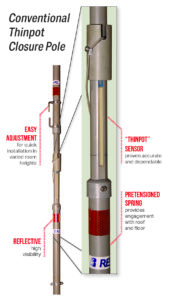

Closure Pole with “Thinpot™” Displacement Sensor

- Designed with a displacement measurement range of up to 12 inches (30 cm)

- One percent linearity displacement sensors typically result in installed accuracy of better than 0.002 inches (0.03 mm) when using a 16-bit datalogger

- Can be easily reset when closure approaches stroke of the instrument

- Conventional closure poles designed for room heights up to 15 feet (4.5 meters), but greater room heights can be accommodated by using a tension closure pole that is attached to the roof and floor using steel cables.

*”Thinpot” is a registered trademark of Spectra Symbol

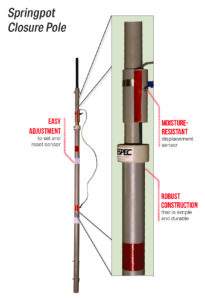

Closure Pole with “Springpot” Displacement Sensor

-

- Features a 1.5-inches (38-mm) displacement sensor with 0.5 percent linearity

- Typical installed accuracy of 0.001 inches (0.02 mm) when combined with a 16-bit datalogger

- Can be easily reset without tools when closure approaches the stroke of the instrument

Extensometers

RESPEC offers a line of inexpensive, nonretrievable single-point borehole extensometers, which are custom built to the client’s application. The borehole extensometers measure displacements within the rock mass and are typically configured to include an automatic warning device that triggers when a preset amount of movement is exceeded. RESPEC’s borehole extensometers can be converted between the “Springpot” displacement sensor and Roof SentinelTM configurations even after the instrument has been installed.

Harpoon™ Borehole Extensometer with “Springpot” Displacement Sensor

- No grouting or special equipment required for installation

- Standard models accommodate 1-3/8 to 2 inch diameter boreholes, but other diameters can be accommodated

- Typical installation time is 10 minutes after the hole is drilled

- Corrosion-resistant construction standard

- Waterproofed sensors available

- Sensor designed to be reset and serviced after installation

- Typically equipped with a 1.5-inches (38-mm) displacement sensor

- Can be combined with Roof SentinelTM warning device allowing for displacement measurements and automatic safety monitoring in a single instrument

- Typical installed accuracy is 0.001 inches

Roof Sentinel™ Extensometer Warning Device

- No grouting or special equipment required for installation

- Standard models accommodate 1-3/8 to 2 inch diameter boreholes, but other diameters can be accommodated

- Typical installation time is 10 minutes after the hole is drilled

- Corrosion-resistant construction standard

- Provides an automatic visual warning when rock displacement exceeds a preset threshold

- Available in strobe light and drop flag configurations

- Can be reset in minutes without tools or additional parts

- Suitable for use in wet or corrosive environments

- Warning devices tolerant of approximately 1g of vertical acceleration

Data Acquisition

Offering a wide-range of products and expertise, RESPEC features a complete line of data acquisition options, from stand-alone dataloggers to research-grade systems.

- For simple applications, RESPEC can provide inexpensive standalone dataloggers.

- RESPEC is an official Campbell Scientific Integrator. When more sophisticated data acquisition systems are required, we design and install sophisticated data-acquisition systems that include real-time notifications and remote data access.