Video Gauge™

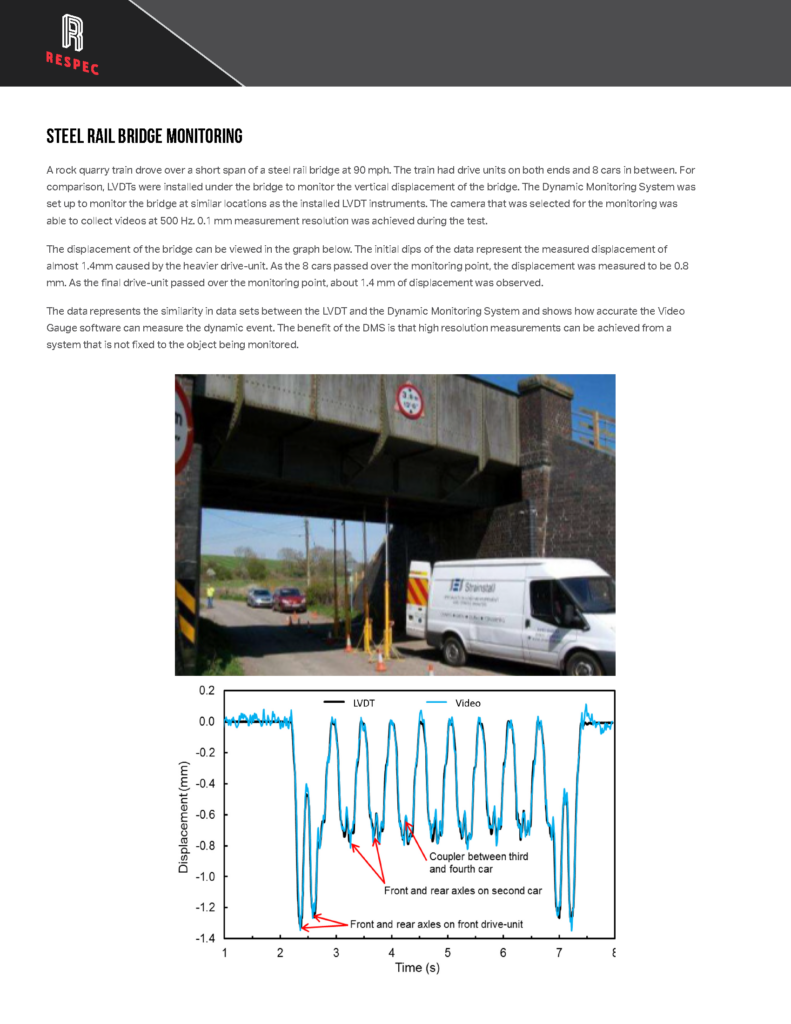

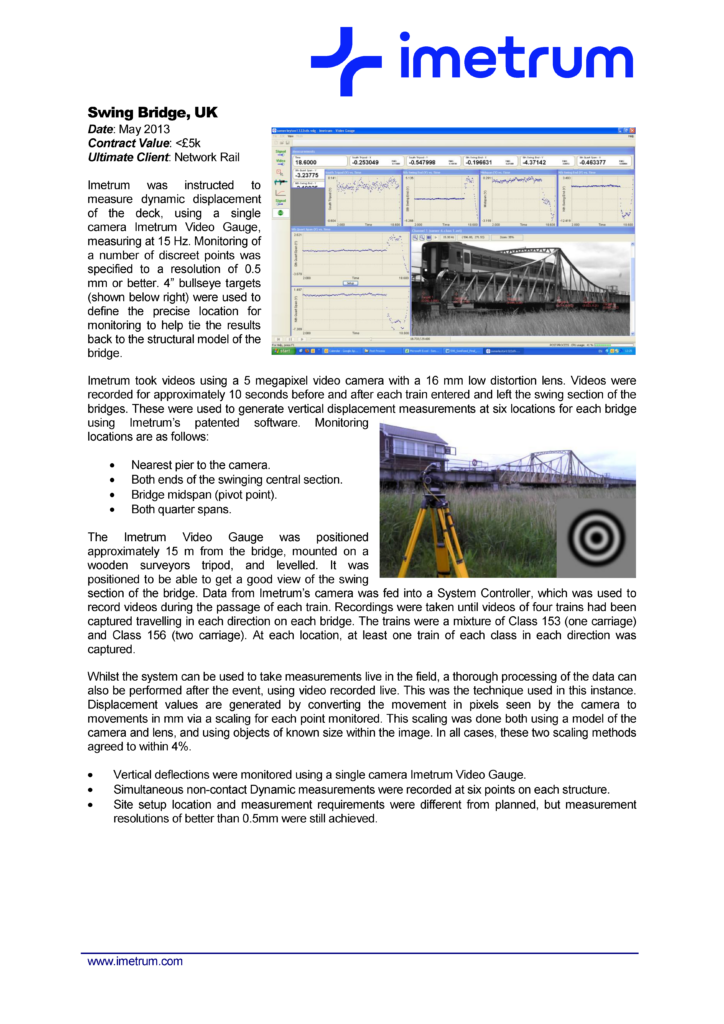

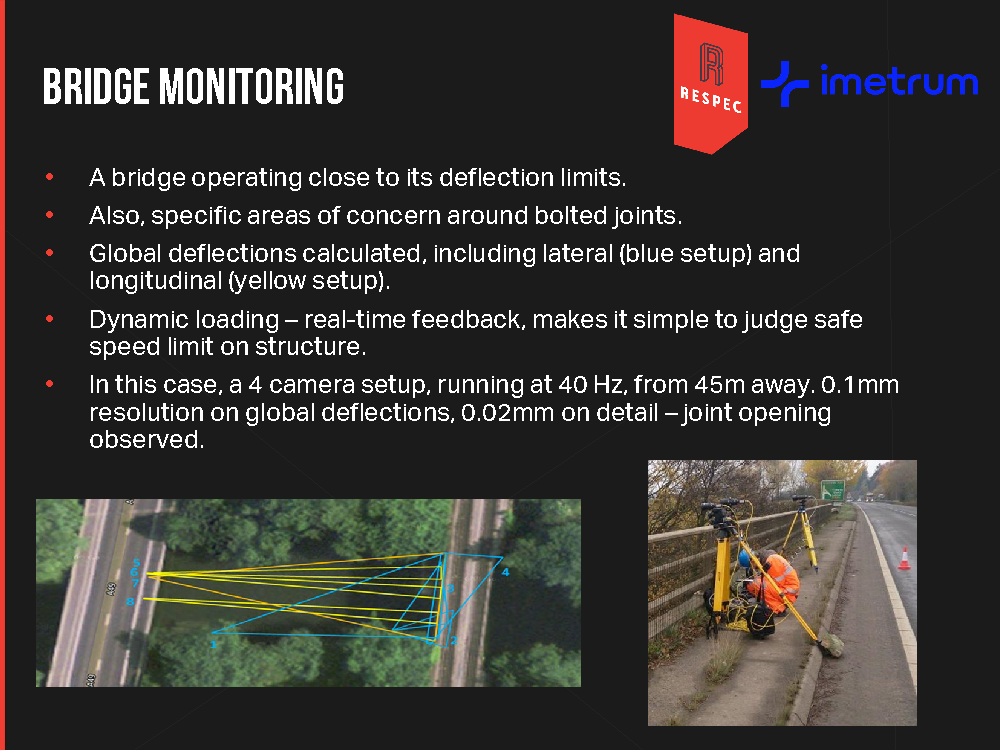

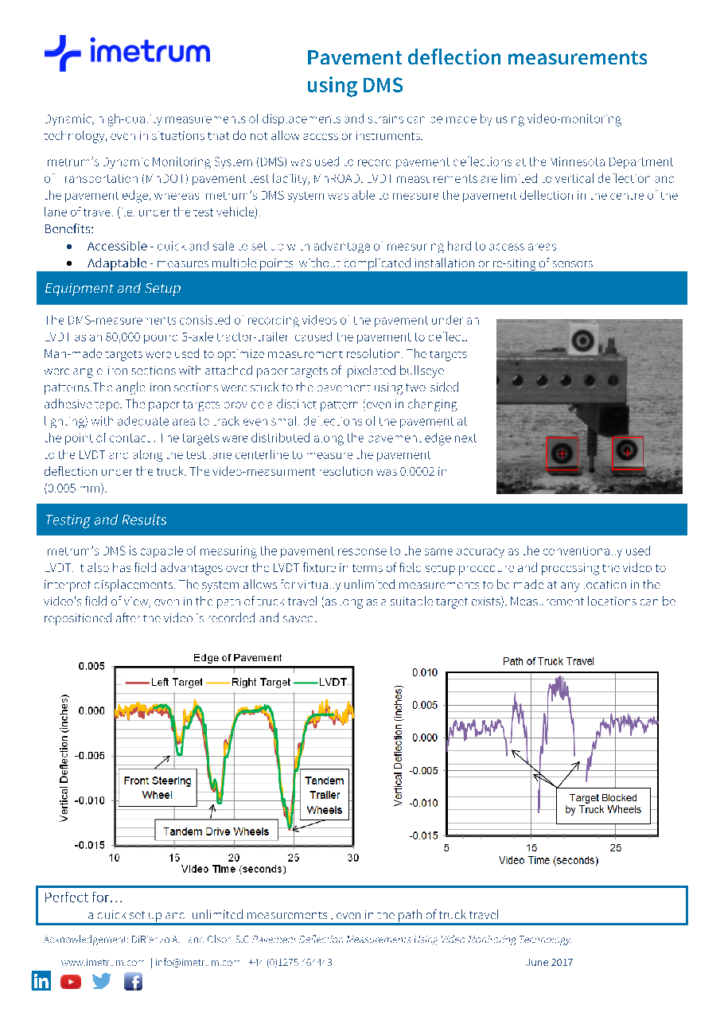

Dynamic, high-quality measurements of displacements or strains can be made using the Imetrum Dynamic Monitoring System (DMS) and Video Gauge™. The non-invasive system can provide you with the data you need even in situations that do not allow access for instruments. The heart of the technology is the specialized software that allows for high-resolution measurements to be made within video recordings. The software uses digital image correlation (pattern-recognition) algorithms that detect changes to “target” positions within the video’s field of view. Varying types of camera and lens combinations make the system versatile for any application. The data can be reviewed in real-time in the field or quickly gathered and saved for post-processing in the office.

Clients use Video Gauge™ for:

• Structural behavior

• Mechanical integrity

• Laboratory and component testing

• Geotechnical monitoring

• Blast and vibration effects

• Bridge deflection

• Rail track movement

• Overhead electrical line sway

• Tunnelling or excavation Impacts

• Subsidence monitoring

• Pavement Deflection

Accurate and Reliable Data:

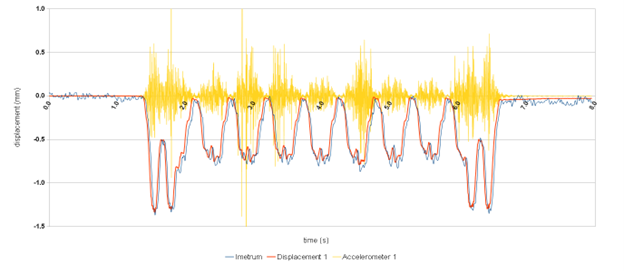

The DMS works with a variety of camera and lens combinations, which support the resolution of data to be collected. Whether your dynamic events occur at high- or low-speeds, camera options are available to suit your applications. Differing lenses allow users to position the cameras near or far from the objects being monitored. Using the proper combination of a camera and lens, you can collect data at sub-millimeter resolution at sampling rates of up to 500Hz.

Monitor Virtual Targets:

A target is simply a portion of the image that has a visible pattern or texture that the software can detect and track. The user defines the targets referencing natural features or installed targets. Any target can be redefined during postprocessing of the videos. Each target’s x and y position (and z position if two or more video cameras are used simultaneously) are resolved for each video frame. Targets can be virtually connected to form extensometers, which can resolve displacement, rotation, and strain between those targets. The multi-point dynamic monitoring system is capable of measurements similar to those generated by strain gauges, LVDT’s, tilt meters, or Total Stations. The benefit of having the video recording of the event provides the user to adjust monitoring locations and the amount of targets during post-processing.

The Complete Solution:

The DMS system is integrated into a ruggedized and portable field case which houses the controlling hardware, a monitor, a mouse and keyboard, and power supplies. Additionally, it has storage for multiple cameras and lenses. This makes the DMS an easily transportable self-contained solution that is setup within minutes saving you time while collecting data.

Safe Deployment of the DMS

Monitoring costs and personal risk are reduced with the ability to monitor dynamic behavior from a distance, often without physical contact of the object to be monitored. Additionally, this prevents the need for closure permissions or interruption to operations. By recording the action with the cameras, you can take the human out of the hazardous environment.

RELATED PRODUCTS

Learn more about related products where RESPEC has proven our expertise in this area.

Stay in Touch